Get Support

123-456-789-10

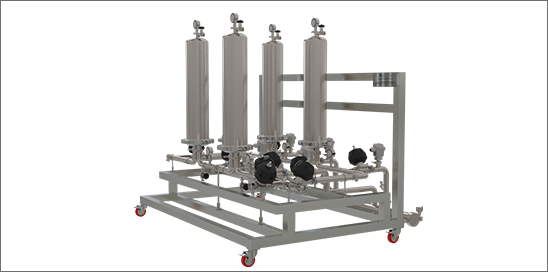

Sanpure Filtration Skids

Key Features and Benefits

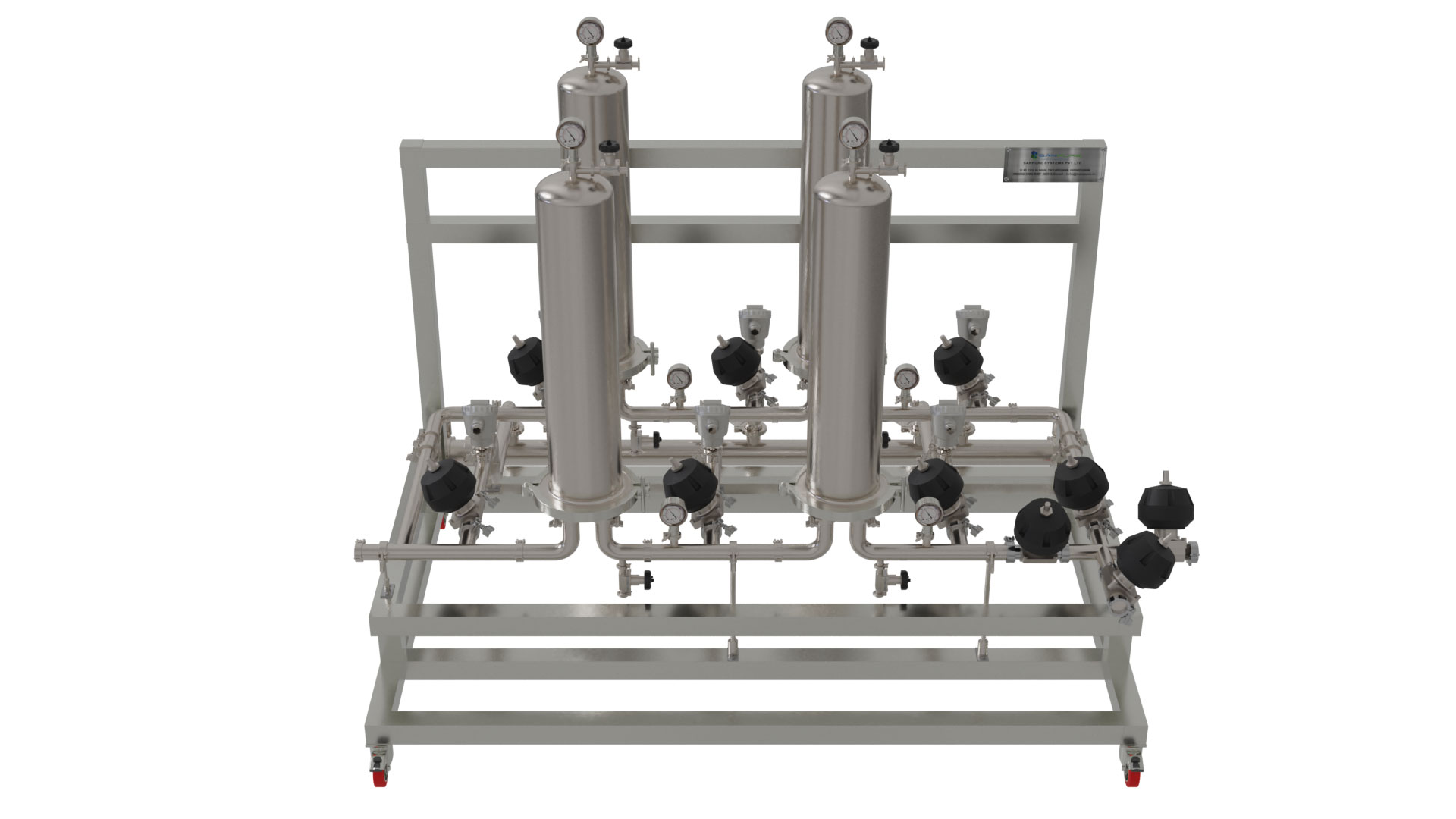

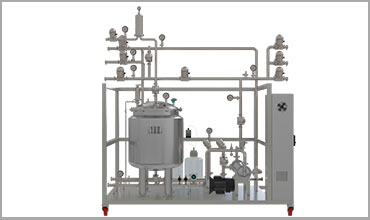

We manufacture wide ranging filtration systems to suit your applications prefiltration for cell / cell debris removal or final sterile filtration of your process fluid, buffer or media. The filtration systems can be designed to handle various capacities to suit your batch volume and flow rates. The filtration skids are designed to be modular and can be scaled up easily to cater to your production capacity expansion. The filtration systems features in-situ CIP and SIP capability and had provision for wetting and integrity testing of the filters.

Sanitary housing design

SS 316L Filter housings, electro polished with <0.3μ Ra internal finish.

Assured Cleanability

Fully sanitary design, 100% cleanability with zero dead legs pockets.

In-situ CIP / SIP capability

Designed for validated and effective CIP / SIP of the filters and media.

Insitu integrity Testing

Provisions for cartridge wetting and in-situ integrity testing of filters.

Compact & Modular

Compact skid design that is modular, scalable and can be seamlessly integrated.

Control & Monitoring

Instruments to monitor differential, pressure, flow and temperature.